{Handling challenging specifications for subzero functions entails professional valve mechanics. Our firm’s freezing 3-way spherical device solutions are crafted to provide consistent performance even at polar temperatures, typically below -150°C. These systems offer extraordinary material control in refined liquids such as nitrogen, oxygen, and argon, frequently employed in branches like LNG, technical equipment, and healthcare facilities. Our experts prioritize strong construction, including smooth-running gasket items and meticulous shaping, to secure closed working. Review the benefits of elevating your cryogenic system with our state-of-the-art 3-way circular valve offers.

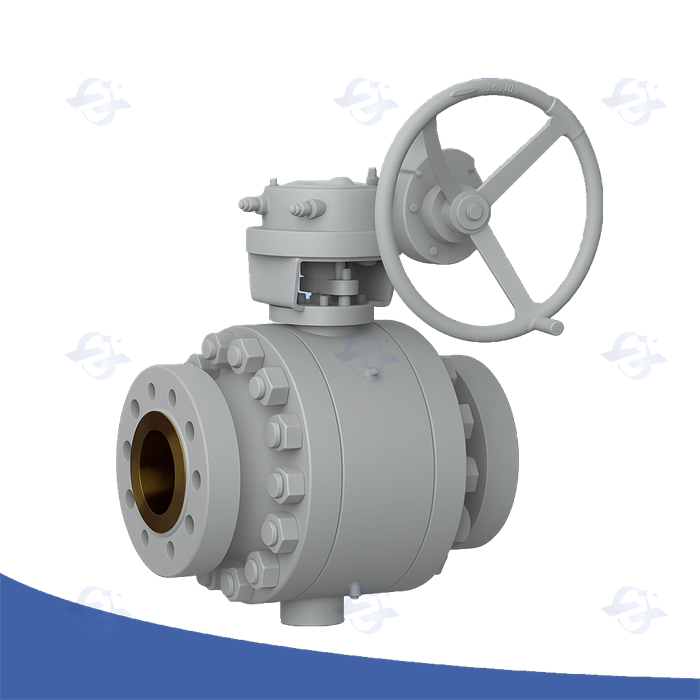

Exceptional Double Block and Bleed Rotational Valve Packages

As for critical systems, particularly where spillage is restricted, leading double block and bleed valve assemblies offer remarkable protection. This novel design incorporates two discrete closure valve seals, supplementarily a bleed channel, allowing for corroboration of the thorough shut-off and diagnosis of any likely seepage. Usually employed in petroleum operations, petrochemical processing, and arctic surroundings, these units substantially enhance service stability and reduce the risk of natural effect.

Three-Way Chilling Circular Mechanism Design

That formulation of triple-port freezing rotary apparatus presents a specific engineering hurdle. These taps are often employed in key industrial uses where rigorous coldness must be maintained. Key issues include matter election, notably regarding vulnerability at diminished temperatures, and the obligation for airtight locking to halt spillage of frosty elements. Sophisticated examination systems and careful creating procedures are indispensable to validate solid execution and permanence under such rigorous performance locations.

Frostbitten Monitor Performance in Engineering Applications

These demanding specifications of chilly implementations, such as condensed natural flammable handling and chilled nitrogen storage, necessitate trustworthy regulator systems. Integral block bleed devices provide a particularly robust and effective solution to achieving zero-leak tightness while facilitating cyclical maintenance. Their design embeds a primary shutoff with a small escape way, allowing administered pressure ejection during ceasing and reengagement. This inherent trait minimizes continuing matter entrapment, thereby ensuring excellent welfare and effectiveness even under the most unyielding employing settings. Furthermore, the potential to monitor outflow stream provides valuable analytical facts for activity maximization.

Securing 3-Way Rotary Valve Locking in Rigorous High-Pressure Situations

Attaining steady tightness performance with 3-way rotary valves becomes particularly important when operating within considerable pressure situations. The design ought to account for significant forces and potential seepage pathways. Specialized components, often including premium metals like long-lasting steel or exotic alloys, are necessary to survive the extreme conditions. Furthermore, advanced interface geometries and exact construction processes are essential to minimize distortion and guarantee a airtight link even under fluctuating stress cycles. Regular examination and preventive preservation programs are as well vital for lifespan and sustained operational stability.

Icy Ball Valve Leakage Prevention Strategies

Decreasing "drip" from cryogenic "rotary valves" demands a multifaceted "method". Initial "blueprint" considerations are paramount; material "decision" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "element", meticulous "manufacturing" processes – including stringent weld "checks" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "openings". A "important" component is proper "arrangement"; thermal "shrinkage" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "repair" – including periodic "supervision" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "framework" incorporating these elements is necessary to ensure the safe and efficient "activity" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "risks", and costly "halt”.

Double-Set Block and Release Apparatus Check Methods

For guaranteeing the integrity and safety of critical piping structures, rigorous combined block and vent instrument assessment processes are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation devices while simultaneously ensuring the discharge device remains functional and correctly discharges any trapped substance. A common procedure is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the exfiltration rate around the closed valves is meticulously documented. The purge instrument's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any outliers observed, is crucial for maintaining a reliable operation.

Comprehending Entire Block Discharge Device Efficiency

For achieving successfully govern pressure frameworks, a complete insight of integral block release apparatus operation is totally necessary. These dedicated modules chiefly respond to reliably free extra power from a assembly during fixed working levels. A routine configuration consists of a fitted chamber associated to the leading power source, permitting one led outflow when needed. The natural structure lowers the possibility of pressure surge, guarding both the tools and the proximate environment. Regular examination and upkeep are vital to ensure optimal capability.

Deciding on the Ideal 3-Way Ball Valve for Cryogenic Fluids

Electing a suitable 3-tri-ball apparatus for cryogenic implementations demands careful analysis of several critical features. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material decision is paramount; only materials with proven conformity and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized metallic alloys, should be considered. Furthermore, the apparatus's sealing capacity is vital to prevent exfiltrations, requiring custom stem sealing models and low-temperature greases. Finally, pressure scales and actuation techniques, taking into account potential pressure jumps, must be attentively matched to the system's demands. Neglecting these considerations can lead to significant failure and safety dangers.

Icy Rotary Valve Material Fitness Handbook

Electing the appropriate compound for cryogenic ball valves is paramount, given the severe temperatures involved. This reference highlights common components and their reaction when exposed to cryogenic fluids such as substance nitrogen, media helium, and oxygen. Stainless steels, particularly kinds 304 and 316, often demonstrate adequate hardness and tarnishing resistance, though martensitic substances require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their bendability and protection to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some positives, may exhibit reduced performance at these minimal temperatures. Consultation with producers and comprehensive testing is essential to verify stability and welfare in cryogenic tasks.

Optimizing Double Shutoff and Vent Configuration Efficiency

Accomplishing optimal work in double shutoff and vent configurations hinges on a multifaceted system. Careful scrutiny of part selection is crucial, with a focus on ingredient suitability and tension classification. Regular assessment of bypass corridors for blockage is mandatory, often requiring the use of expert monitoring devices. Furthermore, technique refinement—including inspection of conveyance rates and pressure disparity—can dramatically strengthen overall application reliability and welfare. Finally, compliance to creator directives and the deployment of a comprehensive overhaul agenda are unavoidable for long-term constancy and lifespan.

API 6D Ball Valve

API 6D Ball Valve