In the domain of industrial operations, upholding the completeness and effectiveness of channels is indispensable. Buildup of contaminants within pipes can significantly hinder fluid dynamics, degrade commodity standard, and adds to maintenance outlays. To manage these complications, tube cleansing systems have emerged as highly effective measures for flawless conduit washing. A pig, habitually a rod-like mechanism, is powered through the pipeline, successfully wiping dirt and guaranteeing top functionality

Duct washing strategies deliver several pros. They are adjustable, ready to sterilizing pipes of different sizes and substances. Furthermore, they are effective, accomplishing the activity in a fairly fast timespan. By diminishing downtime and optimizing pipeline functionality, pipeline cleaning systems advance expenditure savings and expanded operational performance

Sanitation Pigging Methods:

Keeping pipeline cleanness is key for supporting goods reliability and grade of moved commodities. Sanitary pigging approaches deliver a solid way to complete this aim. Pigs, customized contraptions, are launched into pipelines to purify by eliminating residues and debris

- Multiple models of sanitary pigs are offered, each engineered for fixed cleaning functions.

- These pigs are produced from matter that observe stringent sanitary standards.

- Consistent sanitary pigging operations facilitate curtailing product impurity, maintain pipeline durability, and raise complete productivity.

Sophisticated Pigging Technologies for Maximum Capability

pigging systemAcross the area of duct management, advanced pigging systems have arisen as a indispensable asset for assuring optimal efficiency and preservation. These leading-edge systems take advantage of ingenious structures and capabilities to successfully sanitize, evaluate, and defend pipes from degradation. From automated pigs armed with prompt observation components to tailored pigging instruments intended for intricate tasks, progression in this area is perpetually pushing boundaries. By leveraging these forward steps, controllers can notably increase pipeline integrity, lower downtime, and heighten operational output.

Thorough Pigging Solution Formulation and Integration

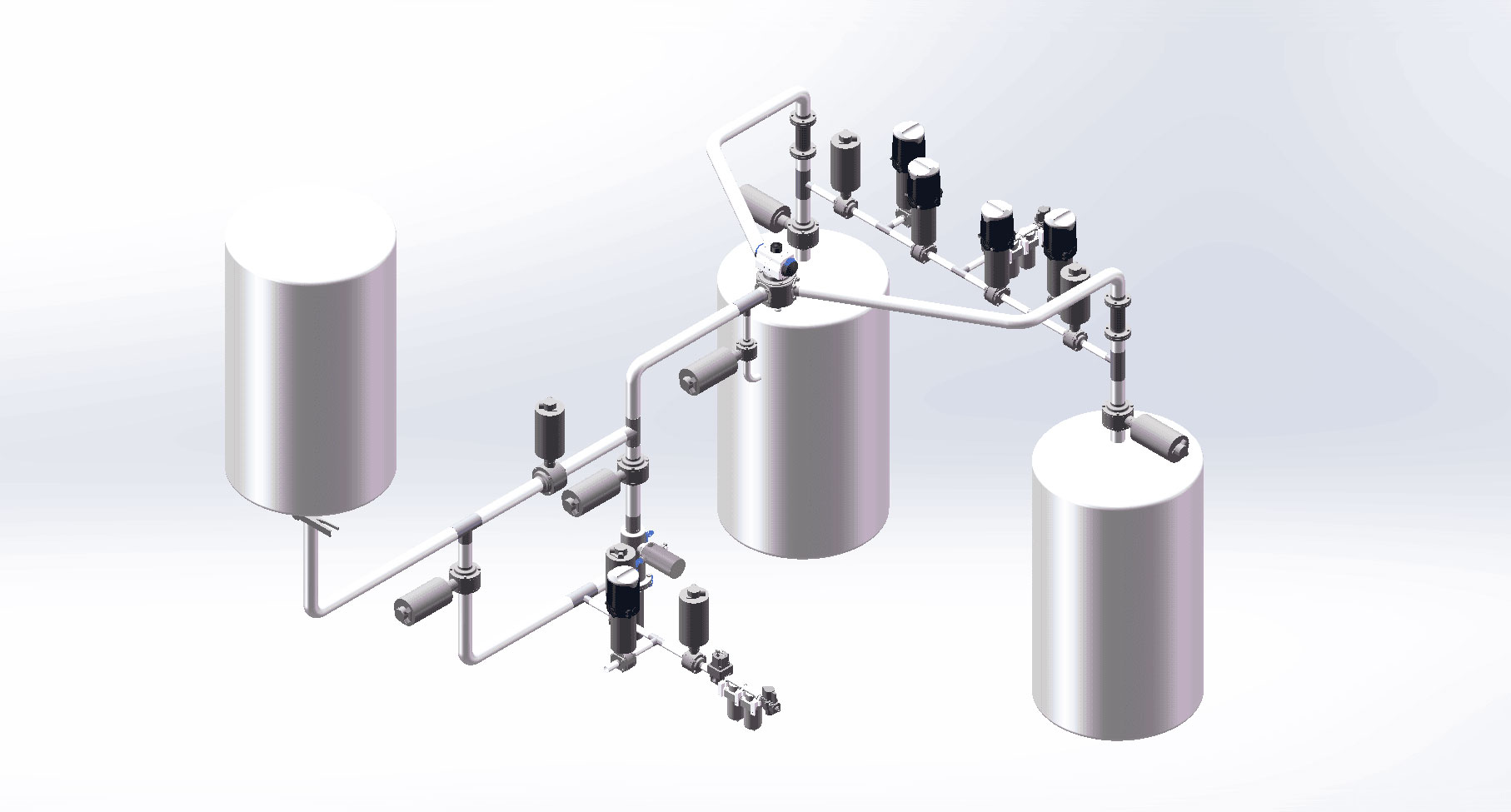

Such all-encompassing pigging system consists of a pivotal strategy for pipeline upkeep. This mechanism incorporates the introduction of purpose-built instruments called pigs, which navigate through channels to sanitize, evaluate, and safeguard their firmness. The blueprint prioritizes considerations such as conduit dimension, material, pig variation, and operational needs. A efficiently conceived system provides potent pigging operations while cutting down downtime and potential injuries. Installation rules necessitate careful preparation, skilled craftsmen, and strict adherence to safety measures to secure a sure and efficient effect

Mechanical Pigging Devices for Varied Assignments

Commercial pigging equipment are key assets used across a vast set of industries. These mechanisms facilitate protected and successful purging, assessment, and conservation of conduits and other tubular frameworks. Pigging incorporates installing engineered implements known as pigs through pipes to execute diverse functions. Standard types of industrial pigging instruments contain cleaning pigs, inspection pigs, and transfer pigs. Cleaning pigs are fabricated to displace debris, build-up, and impurities from pipelines. Inspection pigs are armed with devices that acquire information about the status of pipe surfaces. Transport pigs are utilized to hauler elements through pipelines. The use of industrial pigging products grants numerous positives, such as curtailed downtime, strengthened pipeline soundness, and increased operational productivity. These instruments are broadly utilized in industries such as oil and gas, water treatment, chemical production, and food manufacturing.Full Examination of Pipeline Pigging

Pipeline pigging is an indispensable process used within the oil and gas sphere to monitor pipelines. This key procedure comprises launching specialized gadgets, called pigs, into the passage. Pigs are fashioned to move along the track of the pipeline, undertaking various tasks.

Multiple categories of pigs are accessible, each customized for a specific function. Common uses of pipeline pigging encompass evaluation for defects, flushing, and pipeline rehabilitation.

- Upsides of Pipeline Pigging

- Effects on Operational Efficiency

- Varieties of Pipeline Pigs

Reliable Sanitation using Pigging Setups

Pigging setups grant a stable answer for ensuring sanitation inside pipes. These methods incorporate unique pigs that pass through the line arrangement, effectively cleansing contaminants. The procedure is especially beneficial for areas that expect rigorous antisepsis criteria. Pigging frameworks provide a low-expense and prompt approach for scrubbing passages, reducing the risk of cross-contamination.

Picking Pigging Apparatus for Targeted Specifications

Pigging instruments acts a essential role in powerful pipeline management. When deciding upon pigging apparatus, it is vital to consider the unique demands of your project. This involves assessing details such as pipeline extent, flow movement, product class, and upkeep specifications.

Numerous pigging versions are ready, each manufactured for distinct uses. As an example, some pigs are meant for reviewing, while others are deployed for extracting residue or separating product lots.

In addition, pigging apparatus items should be harmonious with the carried content.

It is commonly recommended to connect with a advisor in pigging systems to make certain that you elect the most appropriate machinery for your particular demands.

Conduit Maintenance Methods - A Practical Approach

Channel purging solutions present a extensive selection of virtues for sectors using passages. By smoothly sterilizing and inspecting line insides, pigging systems contribute to operational performance and cut down maintenance expenditures.

A principal pro of pigging systems is their capacity to clear fouling such as sediments, debris, and oxides. This systematic washing ensures smooth pipeline movement and blocks costly downtime.

What's more, pigging systems can be leveraged to observe the state of pipelines, identifying likely flaws before they amplify into grave hurdles. This tactical method helps to prolong durability of pipelines and reduce overall maintenance expenditures.

Promoting Hygiene in Pigging Processes

Hog husbandry operations substantially lean on appropriate hygiene measures to block the circulation of infections. Adopting rigorous hygiene protocols promotes a vital habitat for pigs, so that causes enhanced health outcomes and productivity.

Regular cleaning and disinfection of premises is necessary to curb the level of harmful pathogens. Proper residues management additionally serves a fundamental part in supporting hygiene.

Moreover, {workers