When dealing with involved grooved pipe configuration and fabricating, joining forces with expert authorities is vital. These seasoned finned tube generation specialists possess a profound knowledge of thermal conductivity principles, alloy behavior, and the latest strategies for creating superior heat exchangers. They oversee everything from planning and prototype development to large batch production and careful assessment. Picking the right fin tube building master can substantially improve the efficiency and stability of your equipment.

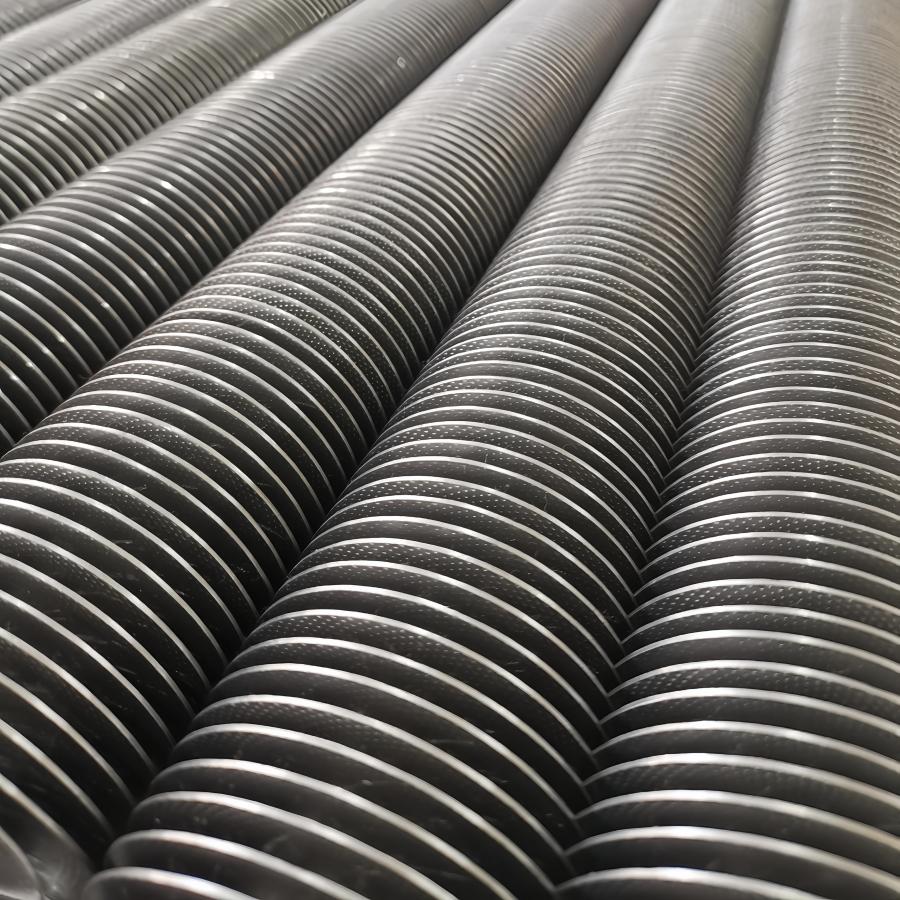

Advanced Serrated Tubing

Leading-edge manufacturing applications frequently demand especially efficient thermal distribution, and top-tier finned conduits are paramount to achieving this. These constituents feature intentionally designed rib geometries, customarily using complicated arrangements to amplify the zone available for warmth conduction. Building methods may entail forming, linked by precision fin development and periodically a exclusive surface processing to beyond improve output. Choosing the ideal finned pipe pattern is influenced on the certain usage modes, including substance elements, heat, and tension levels.

Bespoke Extended Metal-based Tube Systems

Dealing with challenging thermodynamic management necessities? Our expert team crafts bespoke copper tube services precisely for your application. We leverage advanced assembly techniques and meticulous calculations to elevate warmth transmission efficiency. Whether you're in the automotive sector, or need superior cooling in a intricate setup, our augmented copper pipelines can produce superior functionality. We assess factors such as gas passage rates, environmental warmth metrics, and volumetric constraints designed for assemble a truly individual and competent plan.

Advisors in Grooved Aluminum Tube Methods

For several years, we've been dedicated to providing unparalleled expertise in aluminum finned tube design, fabrication, and integration. As leading adepts, we offer a comprehensive group of services, catering to a all-encompassing spectrum of industries, including thermal management, load supply, and chemical engineering. Our workforce of qualified engineers maintains a extensive understanding of heat transfer principles and compound science, ensuring that every job we undertake delivers optimal effectiveness and endurance. We take pride ourselves on delivering customized options that precisely accord with our clients’ unique expectations. Whether you require fin tube repair, replacement, or a holistic system configuration, our focus to excellence remains unwavering. Reach us today to consider your distinct challenges.

Amplified Tube Development and Support Deliveries

Elevating process transfer efficiency is paramount in countless areas, and that's where specialized enhanced tube design and guidance packages truly shine. We extend comprehensive support encompassing everything from initial idea to full-scale installation. Our crew of experienced engineers leverage advanced virtualization techniques and market best systems to produce individualized augmented tube packages for a wide array of intricate environments. Whether you're seeking to improve productivity, reduce resource costs, or address specific system issues, our improved tube expertise guarantees top-tier results. We furthermore offer frequent maintenance solutions to confirm durable productive integrity.

Cutting-Edge Precision Extended Tube Construction

The expectations of modern heat exchanger systems are causing a progression towards highly refined grooved tube approaches. Traditionally, standard fin forms were acceptable, but now applications in technology and factory processing necessitate remarkably tight tolerances and sophisticated geometries. This involves faithful forming of fins directly onto the tube shell, often utilizing sophisticated chill fabrication equipment to gain the desired edge altitude, separation, and design. Furthermore, the composition selection plays a key responsibility, with specialty compounds frequently adopted to raise thermal operation while maintaining mechanical durability. Benchmark testing mechanisms are also paramount to guarantee regular textured tube rank.

Augmented Copper Pipe for Heat Exchangers

Modern heat exchange systems frequently incorporate finned copper duct as a crucial part in heat exchangers. The integration of fins, frequently made from soft metal, significantly magnifies the surface space available for heat distribution, leading to a amplified efficient heat conversion. These improved copper tubing are commonly found in applications ranging from industrial processes, such as cooling machinery, to residential HVAC systems. The superior thermal conductivity of copper, associated with the extended surface area coverage provided by the fins, brings in a profoundly effective method for directing heat. heat exchanger tube bundle Different fin arrangements, including linear and curly, deliver varying degrees of performance refinement depending on the particular application’s needs.

Modern heat exchange systems frequently incorporate finned copper duct as a crucial part in heat exchangers. The integration of fins, frequently made from soft metal, significantly magnifies the surface space available for heat distribution, leading to a amplified efficient heat conversion. These improved copper tubing are commonly found in applications ranging from industrial processes, such as cooling machinery, to residential HVAC systems. The superior thermal conductivity of copper, associated with the extended surface area coverage provided by the fins, brings in a profoundly effective method for directing heat. heat exchanger tube bundle Different fin arrangements, including linear and curly, deliver varying degrees of performance refinement depending on the particular application’s needs.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum enhanced tubes offer a compelling combination of streamlined construction and remarkable functionality, making them ideal for a varied range of manufacturing heat transfer systems. Their unique structure—featuring aluminum flanges attached to the tube coat—significantly enlarges the heat exchange capability without adding substantial mass. This translates to reduced energy charges and improved overall equipment consistency. Consequently, these tubes are frequently chosen in HVAC systems, refrigeration, and other heat dispersion processes where minimizing heaviness and maximizing temperature transfer are paramount considerations.

Finned Tube Fabric Options: Cu & Aluminum

In the event that deciding on finned tube compound, engineers frequently examine copper and aluminum. Copper offers exceptional degradation tolerance and superior temperature distribution, making it fitting for applications where productive heat flow is paramount, such as in air conditioning systems. However, copper's heightened charge and potential for galvanic corrosion with other components can be limiting constraints. Conversely, aluminum provides a significantly lower expense and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Boosting Heat Conduction with Finned Sections

The productivity of heat exchangers frequently hinges on the design and realization of finned tubes. These structures significantly amplify the surface area available for heat convection, allowing for a much greater dispelling of heat compared to simple, unfinned pipes. The boost process involves a complex interplay of factors, including fin shape – such as fin scale, spacing, and gauge – as well as the element of both the fins and the foundation lines themselves. Careful consideration of the fluid flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat removal isn’t restricted by boundary layer effects or uneven allocation of the working material. Ultimately, a well-designed finned channel array delivers a remarkable improvement in overall thermal efficiency within a given space.

Strong Finned Tube Networks for Manufacturing Applications

Accommodating the requirements of demanding commercial environments necessitates resilient heat conduction installations. Our finned tube collections are engineered for exceptional longevity, providing reliable heat conveyance in a range of applications, from power processing to air handling control. Constructed from premium materials and featuring advanced material durability techniques, these items minimize repair downtime and maximize operational efficiency. The bespoke fin geometry promotes increased heat distribution, even under challenging operating conditions.