dynamic corrugated packaging maker why invest in dedicated packaging box fabricators for specialized needs?

Explore the intriguing domain of corrugated carton production via this all-encompassing explanation. This overview highlights the important actions in modifying simple substrates into firm parcels that safeguard items throughout shipping. Incorporating flute crafting, printing, and finishing, we discover the subtleties of this important domain.

- Learn about the various forms of corrugated cartons and their unique uses.

- Review new breakthroughs in packaging production.

- Learn about the environmental effects and green manufacturing methods.

If you are a novice, consultant, or business fan, this handbook presents essential data about the progressing packaging industry.

Building Concepts through Corrugated Substrate

Corrugated board, usually ignored as elementary packing substance, functions as a multipurpose crafting medium. Its solid essence backs the assembly of fresh constructions and styles, ranging from functional storage solutions to whimsical decorative pieces. Through inventiveness, you may change this ordinary element into something outstanding.

Investigate the vast chances of corrugated sheet fabrication using:

- Utilizing several procedures including cutting, creasing, and layering

- Integrating reclaimed items for an earth-friendly approach

- Revealing your pieces to influence others

With its affordability, accessibility, and versatility, corrugated cardboard is a perfect material for crafting enthusiasts of all ages and skill levels. Tap into your artistic side and allow your innovation to soar using this modest material.

The Science and Craft of Cardboard Container Design

Corrugated packaging design is a captivating blend of science and artistic expression. It's not simply about constructing a box; it's about crafting a protective vessel that preserves goods throughout shipment while also making a visual impact on customers.

A skilled designer understands the intricate properties of corrugated cardboard, modifying its measure, flute shape, and composition to match individual prerequisites of each item.

- In addition, artistic elements are critical.

- A carefully crafted box becomes immediately identifiable in a store, enticing the focus of future clients.

- Chiefly, packaging formation harmonizes safety and aesthetic.

Fulfilling Orders: Boosting Your Container Manufacturing

With successful operations and escalating orders, it's imperative to maintain capacity for addressing client demands. Elevating box production could facilitate steady functioning and strengthen reputable status.

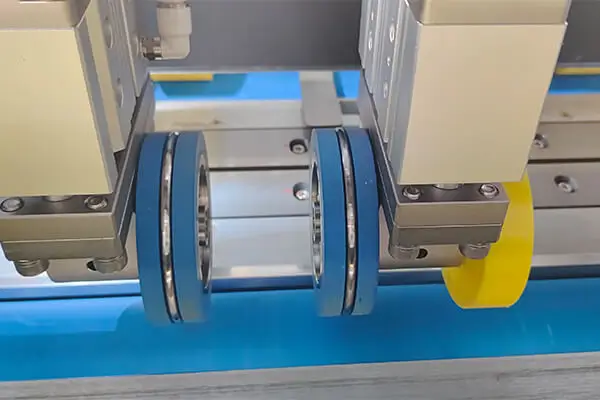

Primarily, analyze your production processes. Survey deployed equipment and crew to recognize likely slowdowns or areas for development. Afterward, investigate approaches for boosting production capability. Deliberate on securing innovative tools or improving present equipment to escalate production.

Understand that expanding numbers is less vital than perfecting total workflow. Incorporate effective manufacturing practices to decrease refuse and enhance input utilization. Streamline workflows, automate repetitive tasks, and invest in employee training to create a high-performing team.

Finally, foster strong relationships with your suppliers to ensure steady raw material flow. By implementing these strategies, you can successfully scale your corrugated box production and meet the growing demand of your customers.

Improvements in Cardboard Fabrication

The packing area steadily improves, energized by desires for eco-conscious, cost-effective, and original strategies. Corrugated board, a reliable material for long, enjoys rebirth fueled by cutting-edge breakthroughs. From robust constructions to interactive elements, corrugated material adopts upcoming trends. Constructors analyze fresh techniques to elevate carton abilities, incorporating environmentally friendly components and workflows. The consequence is a stream of innovative packaging plans altering the sector panorama.

These innovations address key challenges facing businesses, such as reducing waste and optimizing logistics. Shoppers also take advantage of these developments, using packaging that is tougher and more practical. The future of corrugation is bright, filled with potential to create a more sustainable and efficient packaging ecosystem.

Eco-Conscious Corrugated Packaging: Sustainable Selections

Corrugated parcels form a key part of modern transportation chains. Usually created from stock, such packages carry important implications for habitats. Despite this, amplified awareness of green procedures concerns carton fabrication. Thankfully, cutting-edge methods are present to elevate eco-friendly traits of such shipments.

A vital component embraces applying recycled pulp. By incorporating production or customer discards, the desire for untouched fibers declines, conserving woodlands and environmental assets.

Likewise, suppliers allocate funds to earth-friendly production systems. Such efforts encompass improving fuel efficiency and curbing scrap along logistics channels. Consumers can also play a role by choosing corrugated boxes that are certified as sustainable. Review logos such as FSC or SFI that validate responsible sourcing and fabrication.

By utilizing these techniques, we copyright cartons as key commercial assets while lessening environmental consequences.

Preserving Excellence in Carton Creation

Securing excellent results in packaging assembly requires rigorous testing procedures. From the initial sourcing of raw materials to the final inspection of finished goods, every step demands unwavering attention. Tight regulations control all manufacturing steps to verify each package fulfills superior requirements.

- Analyzing base constituents for defects, strength, and consistency is imperative to obstructing subsequent problems.

- Observing strict specifications and parameters during trimming and molding secures containers are physically reliable and appropriate for function.

- Periodic inspection of print quality assures vivid pictures and distinct type

- Applying technology-based checking frameworks advances accuracy and throughput in inspection procedures

By stressing rigorous checks during manufacturing, producers offer packages that are sturdy and eye-catching. Such attention to detail appeases consumer desires and fortifies brand credibility.

Corrugated Box Printing: Branding and Impact

Packaging decoration printing forms a significant component of brand impression. When customers observe your articles, the box functions as a vital channel for expressing brand identity. A thoughtfully developed image on a container can draw focus, represent brand character, and promote purchase behavior.

Moreover, carton printing provides a variety of possibilities to personalize your parcels. Utilizing dazzling colors to novel symbols, it is feasible to communicate brand traits via packaging shape.

Ultimately, packaging branding is beyond necessity – it operates as an influential means to strengthen brand awareness and engage your audience.

From Base Components to Final Goods: The Corrugated Carton Process

The construction of packaging is a remarkable process changing basic ingredients into a vital delivery and containerization method. It all begins with the procurement of pulp, typically derived from recycled sources. Then, pulp is formed into sheets of corrugated sheet, having a fluted core trapped between two flat liners.

These boards are rigorously cut to exact specifications, then bonded with dedicated equipment to fabricate the desired packaging design. Adhesives play a crucial role in sealing the components together, ensuring a strong and durable structure.

At last, packages face thorough evaluation routines to confirm physical soundness and adherence to market criteria.

Arising from unassuming starts, the parcel becomes a dynamic packaging marvel, suitable to preserve broad merchandise during transport.

Global Packaging Industry: Trends and Openings

The global container market faces a time of increase. This lively industry is motivated corrugated box maker by expanding client needs for shipment. Core drivers encompass growth of digital retail and need for eco-friendly parcels